As a manufacturing business, you know traditional visual inspection manufacturing has limitations. Humans are prone to making errors, face fatigue, and have high escape rates.

A modern solution for medium-large manufacturing industries is optimizing for visual inspection using modern technologies. It’ll give you an uptick in quality control and reduce the risk of selling defective products to customers.

Besides, you don’t have a record of what the inspector saw, but you only have the call they made during a manual inspection. In a nutshell, traditional quality control checks in manufacturing are inefficient.

The solution? AI-powered visual inspection! It brings 80% more accurate inspection results in the manufacturing industry. Recently, IBM used AI to perform visual inspections for a popular car manufacturer, showing it improved their defect detection and quality.

Integrating artificial intelligence into your visual inspection manufacturing process will help optimize quality control, reduce defect piece production, increase sales, and maintain the standard quality of your overall production lines. In this post, you’ll learn about different modern technologies that can help and the benefits of using them.

Challenges of traditional visual inspection

As a manufacturing company, you work hard to deliver the best quality products for your customers. However, the manufacturing processes are complex, as large quantities are produced daily.

Your company has to ensure the proper machinery location and match colors and textures free from defective combinations or blemishes. These inspections are difficult with manual visual testing. However, using AI, you can easily solve most of these challenges (more on this below).

Subjectivity and human error

Human inspectors in larger companies have the highest work risk, as a small mistake or inconsistent attention can lead to a big defective production. Even with random sampling, there is a chance that the whole production batch will be harmed if defects are missed in the sampled items.

Inspectors can fail to interpret human error, which can cause the desired product not to match expectations. Fatigue and varying levels of attention can cause defective products and, ultimately, companies to bear a huge loss.

Speed limitations

Humans will never match the speed of AI with machine learning programs, and it is difficult for human inspectors to keep up with the high-speed production lines and fix their defects.

This slow process reduces the overall production efficiency, whereas automated visual inspection boosts it to be much better and faster.

Inability to detect subtle defects

A human naked eye can miss detailed and small defects of the overall production pattern that can indicate larger issues. This can produce defective products that eventually reach customers.

For instance, look at the textile industry, where there is a high chance of color inconsistencies that may go unnoticed by human inspectors. The whole cloth production will reach customers as a defective piece, which can cause big losses for the company.

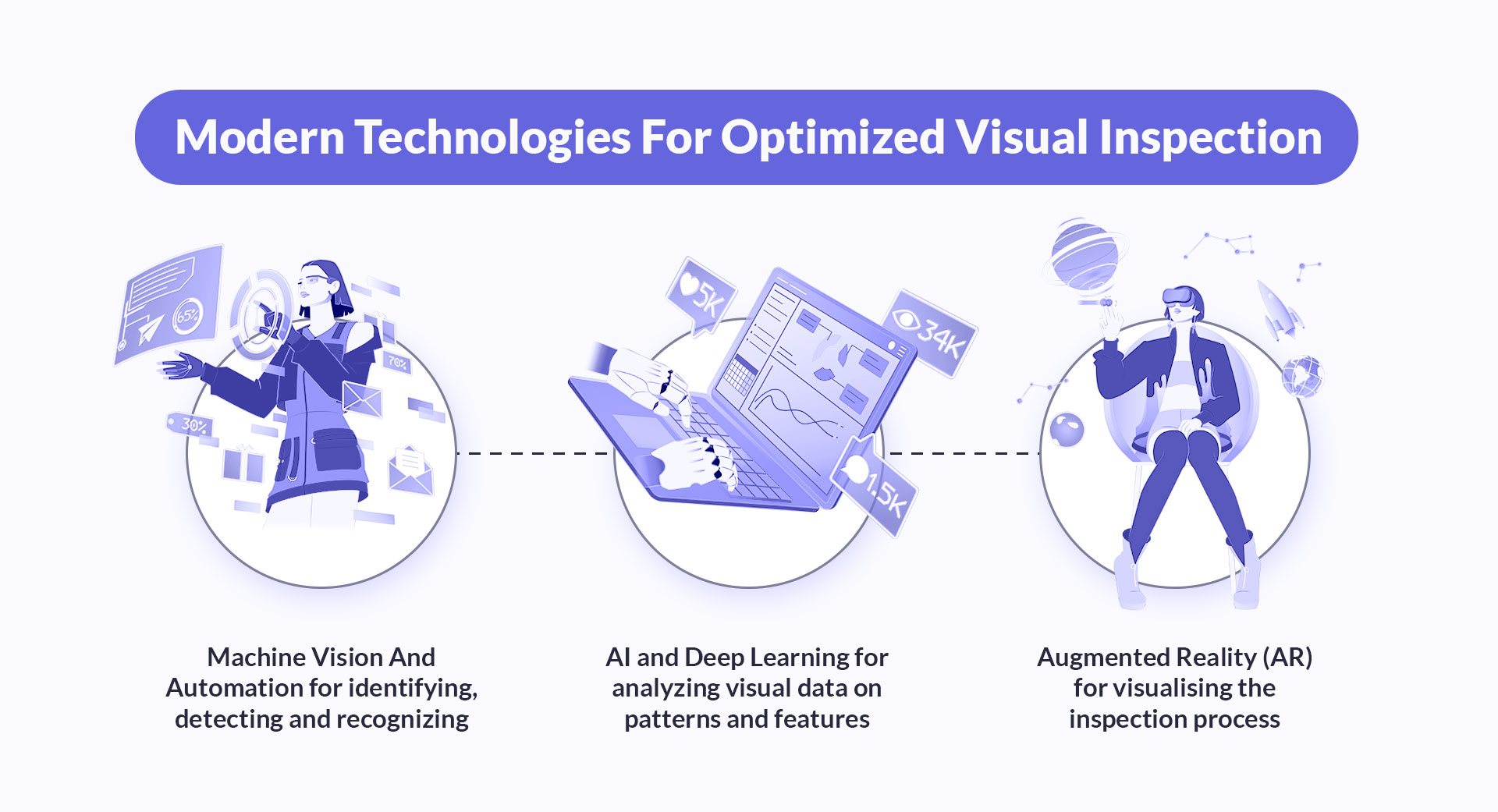

Modern technologies for optimized visual inspection in manufacturing

1. Machine vision and automation

Modern technology helps optimize the product's proper dimensions, shapes, and colors, specifically identifying the smallest details and eliminating defects. It ensures detailed specifications match the desired product features and specifications.

Further, machine vision and automated visual inspection easily identify inconsistencies and directly indicate the defects found during production. Detecting small imperfections such as normal scratches, dents, or color mismatching becomes important. If addressed, this may produce defective batches.

Automated visual inspection also helps recognize patterns to classify defects in designs. The system will accurately sort products based on the defect classification, so there is no chance of good products getting rejected. Electronics pattern recognition helps identify the defects on the circuit board level and classifies them for sorting.

2. Artificial Intelligence (AI) and Deep Learning

Artificial intelligence can help detect the class and location of multiple objects in an image. Thanks to object recognition and the ability to train models specific to each manufacturing context, computers can effectively identify things in pictures.

AI algorithms use deep learning techniques to analyze visual data on patterns and features. This modern system can easily detect defects and minor flaws like cracks, missing components, or automotive parts by accepting a database of acceptable product standards.

AI can also help you flag deviations from the expected appearance of a product. The AI algorithm will learn the normal pattern of the production and identify the anomalies that indicate the defects or any irregularities seen during the assembly. This helps in sectors like the agricultural process. For instance, drones equipped with AI can easily scan fields for anomalies in the overall crop health. Crops that are not well grown or found to be nutrient deficient will be easily detected.

But best of all, AI can sort products or objects based on defects or severity. So, it gets classified and lined up according to different classes. In retail, AI-powered systems can easily be classified based on visual attributes like color, size, and style. This will help automate the overall inventory management, ensuring the products are correctly organized.

3. Augmented Reality (AR)

Augmented reality enhances the overall visual inspection process in production. It has various use cases, helping multiple industries with quality checks that lead to a better business reputation.

Augmented reality overlays the digital instructions from a quality control inspector, which helps guide complex procedures with visual cues in the production line. For instance, aerospace inspectors use AR to follow the assembly steps to identify defective parts on aircraft components to prevent major accidents.

Additionally, AR provides interactive visual aids that shorten training periods by offering immersive simulations of the visual inspection process. A pharmaceutical inspector will identify defects on virtual samples before the final round of the AR inspection processes.

Lastly, it also helps experts remotely assist inspectors by sharing their AR view and providing on-the-spot, real-time guidance. The oil and gas industries have inspectors who receive annotations and help from experts via AR glasses during pipeline inspections. Remote visual inspection helps perform the quality checks before the product is dispatched.

![AI in manufacturing — full guide [2024]](https://geniusee.com/storage/app/media/blog/blog_321_ai-in-manufacturing-full-guide/ai-in-manufacturing-full-guide-seo.png)

More from our blog

AI in manufacturing — full guide [2024]

Check out our comprehensive guide on how AI can transform your manufacturing business.

Read nowImplementing modern visual inspection systems

- Identifying inspection needs

Identifying the bottlenecks and challenges that the manufacturing industry faces is important. Once an area for improvement is identified, AI visual inspection in manufacturing can be developed and implemented.

Specification challenges can be diagnosed when you keenly implement a visual inspection solution. Every manufacturing industry requires different types of inspection quality checks. Hence, identifying what exactly your company requires as a product outcome is the first task.

- Choosing the right technology

Then, it is important to select the right technology. The volume of products should also be inspected under budget constraints. Technologies like AI-powered image recognition and machine learning AI algorithms can bring accuracy to your production line.

- System integration

Any AI system you implement should seamlessly integrate with your existing manufacturing visual inspection production lines so it doesn’t disrupt workflow setup. The visual inspection should be compatible with the current automation and data systems to ensure smooth data exchange.

- Training and support

Authorized candidates in your company need to understand and operate with a deep knowledge of the overall inspection system.

Real-time support is essential for troubleshooting issues and gradually maximizing overall system efficiency. Proper training programs and 24/7 support ensure the visual inspection system in manufacturing industries gives reliable performance.

Needless to say, implementing these modern inspection systems is a challenging task. You must take proper precautions so it fits your existing visual inspection.

Alternatively, you can get help from a reliable company, like Geniusee, to utilize AI integration services. Geniusee has AI experts who have worked with various industries, including manufacturing. Their team is highly specialized, has years of experience, and will address your specific needs.

Benefits of optimized visual inspection

Improved product quality. You can largely reduce the defect rates with optimized visual inspection. The computer vision ensures that minor details are detected, decreasing quality issues, satisfying customer expectations, and ultimately increasing sales. There will be real-time defect detection that can prevent manufacturing batch loss and contact customers. It will enhance brand reputation and customer satisfaction.

Increased production efficiency. Visual inspections are faster than manual inspection, so it leads to faster production and minimizes overall production line downtime. Also, the manual sampling process makes it easier to ensure timely delivery of products to customers without defects.

Cost savings. As visual inspection spots product defects on the production line or at the assembly point, there will be no products returned for rework. Ultimately, there will be a decrease in the scrap produced from defective products, and it will overall improve the yield, where the maximum product meets the quality standard decided by the companies.

Enhanced data collection. Automated visual inspections provide real-time data, which can help your business fetch valuable insights for improvement. For instance, you can use the data to identify ongoing trends, predict issues, and make adjustments in production to ensure customers are satisfied with the ongoing quality produced.

Thank you for Subscription!

Conclusion

Computer vision will never lie. Using visual inspection models in manufacturing industries can save time, money, and effort. Human senses tend to make mistakes or miss minor defects during manufacturing. But, trained models, like artificial neural networks, mimic and adapt the human senses and brain. Not only spotting the defect, but a full manual sampling process can be avoided.

Now you know why modern visual inspection is crucial for manufacturing companies. Whether it is remote visual inspection using AR or AI-integrated inspectors, an optimized system can handle the big production line in your manufacturing business. It helps avoid financial loss or incurring a bad reputation.