Artificial intelligence (AI) is not merely enhancing logistics — it has become the conductor of a complex symphony, orchestrating supply chain management with data-driven predictions, autonomous IoT systems, and human collaboration. AI in logistics redefines global goods movement and supply chains: it helps engineers remove bottlenecks, anticipate disruptions, and turn supply chain inefficiencies into opportunities for growth.

From predictive analytics (e.g., demand prediction based on multiple factors) and machine learning to autonomous technologies, logistics companies use AI-powered custom software solutions to upgrade inventory management and optimize everything, including last-mile delivery. As these systems evolve, they create operations that are not only more precise but also more resilient and adaptable.

The global market for AI in logistics and transportation is projected to grow significantly — from $2.1 billion in 2024 to nearly $6.5 billion by 2031, with an annual growth rate surpassing 17%. Despite this rapid growth, the logistics industry still grapples with poor orchestration in many areas. A lack of synchronization among suppliers, manufacturers, and distributors leads to numerous logistical issues:

Refrigerated goods spoiling due to delayed shipments

Delivery disruptions caused by inefficient routing

Bottlenecks arising from unsorted warehouse inventory

Insufficient transparency hindering supply chain visibility

Missed opportunities to reduce costs and minimize environmental impacts

Logistics companies use AI to address these inefficiencies. Acting as a unifying force, artificial intelligence in transportation coordinates collaboration across fragmented networks to improve their synchronization, enable smarter decision-making at every step of the supply chains, and elevate overall logistics performance.

The role of AI in modern logistics

AI in transportation and logistics is tackling some of the most pressing challenges in the industry with remarkable precision. Inefficiencies — fuel overuse, delivery delays, and poor coordination — have long plagued supply chains, driving up operational costs and hampering customer satisfaction. Logistics companies are transforming how goods move and services are delivered by deploying custom machine learning, predictive analytics, and autonomous systems.

According to earlier studies conducted by McKinsey and other researchers, AI has demonstrated measurable improvements across various logistics operations. This data underscores the impact of artificial intelligence on transportation and supply chain management. The quantifiable benefits of logistics and artificial intelligence extend far beyond cost reduction:

AI-optimized routing can lower fuel consumption by over 15% annually.

Intelligent maintenance systems cut repair costs by approximately 20–30%, reducing downtime and extending fleet lifespans.

Autonomous vehicles and telematics have reduced accidents in pilot programs by as much as 40%.

Anomaly detection tools flag issues like temperature fluctuations in cold chains or unsafe driving behaviors during transportation.

AI-powered warehouse systems improve order accuracy and reduce sorting times by significant margins.

Category | AI Solution | Benefit |

Route Optimization | Machine learning algorithms integrated with geospatial data and GPS technologies to optimize delivery routes. | Reduced fuel consumption |

Predictive Maintenance | IoT sensors combined with AI analytics and Generative AI development to simulate potential failure scenarios and improve system reliability. | Lower repair and downtime costs |

Safety Improvements | AI-powered telematics systems paired with computer vision for monitoring driver behavior and autonomous vehicle control. | Fewer accidents |

Risk Detection | Advanced anomaly detection systems using logistics artificial intelligence alongside cloud platforms to flag supply chain disruptions in synchronous mode. | Real-time issue identification |

Warehouse Efficiency | AI-driven robotics combined with automated guided vehicles (AGVs) and vision systems for seamless order sorting and inventory handling. | Faster order fulfillment |

Key applications of AI in logistics

Artificial intelligence logistics transportation is improving the industry with a diverse range of applications that address longstanding inefficiencies and modernize operations. Below are the primary use cases showcasing how logistics artificial intelligence is making an impact:

Demand forecasting

AI in logistics plays a critical role in predicting demand with higher precision, ensuring optimal inventory levels. Advanced predictive analytics tools like those integrated with Google Vertex AI analyze historical sales data and seasonal patterns to forecast product requirements. These benefits of AI ensure better supply chain responsiveness and significant cost savings. For example, our work on a custom AI-driven manufacturing system for demand prediction achieved:

Improved demand prediction accuracy by about 8%, ensuring timely deliveries and reducing stock shortages

A 10% reduction in excess inventory, freeing up valuable warehouse space while cutting storage costs

Route optimization

Logistics and artificial intelligence are flawlessly combined for better route planning: generative AI consulting solutions combine machine learning algorithms with real-time traffic data and geospatial mapping. These systems optimize delivery schedules, minimize fuel consumption, improve shipment quality, and reduce transit times. Companies using these AI systems in logistics and transportation report fuel savings exceeding 15% annually, making a tangible difference in operational efficiency and sustainability.

Warehouse automation

AI in logistics also extends to warehouse operations, where robotics and intelligent systems perform core functions such as sorting, packing, and inventory management. Our collaboration on the Nimble AI project introduced a versatile robot powered by custom AI metrics and a redesigned data pipeline. Key outcomes included:

Reduced latency — items were registered in the system in under 30 seconds from arrival

Tripled cost efficiency compared to the original setup

Enhanced issue identification, reducing resolution times to just 30 minutes

The integration of AI technology ensures seamless orchestration of warehouse processes, improving efficiency and accuracy.

Supply chain visibility

Real-time tracking and monitoring are pivotal in logistics and supply chain management. Businesses gain end-to-end visibility in their operations by deploying AI systems integrated with IoT devices and cloud platforms. For example, anomaly detection tools flag potential issues — such as temperature variations in cold chain logistics — before they escalate, ensuring quality control and reducing spoilage risks.

Customer service enhancement

AI-powered virtual assistants and chatbots are bringing new capabilities into customer interactions. These AI technologies automatically handle inquiries, update shipment statuses, and resolve common issues in live chat mode. Logistics companies adopting these intelligent systems report faster response times and increased customer satisfaction, proving that logistics and artificial intelligence go hand in hand in enhancing the user experience. AI in logistics continues to evolve, unlocking innovative solutions and setting new standards for efficiency, accuracy, and customer satisfaction across the industry.

More from our blog

Financial business intelligence: The key to unlocking profitability

Financial business intelligence boosts decision-making, efficiency, and growth. Here's how to begin!

Read moreBenefits of integrating AI in logistics

The integration of AI technology in logistics addresses existing supply chain inefficiencies, enhances every link’s reliability, and cuts overall process costs. Predictive maintenance, a cornerstone of AI in logistics, uses real-time sensor data to identify equipment anomalies early, reducing downtime, avoiding costly repairs, and extending asset lifespan.

AI streamlines fulfillment by automating tasks like picking and packing, and grouping items efficiently to save time and minimize errors. AI-driven order validation systems catch inconsistencies — such as incorrect addresses or unusual item combinations — early, preventing disruptions and ensuring smoother operations.

Autonomous vehicles, such as those developed by UK-based Wayve, bring practical advancements to urban logistics and last-mile delivery by improving speed and cutting labor costs. These self-driving systems can also integrate with warehouse robotics, creating seamless workflows that enhance overall efficiency. In global trade, companies like Maersk use AI to analyze complex supply chain networks, identifying key priorities and addressing bottlenecks to ensure smoother operations.

AI benefits in logistics and transportation

- AI-powered autonomous vehicles

Unmanned ground vehicles (UGVs) and unmanned aerial vehicles (UAVs) enable deliveries in challenging terrains or congested urban areas. UAVs (drones) offer rapid last-mile delivery for small parcels, while UGVs optimize cargo transport in warehouses or between facilities.

Manpower optimization

AI systems automate repetitive tasks, allowing workers to focus on strategic roles like engineering and problem-solving, driving innovation and long-term growth. For a real-world example, explore our 3PL fulfillment software development case — where we partnered with an autonomous logistics company to create software that streamlined order processing and delivery across multiple platforms.

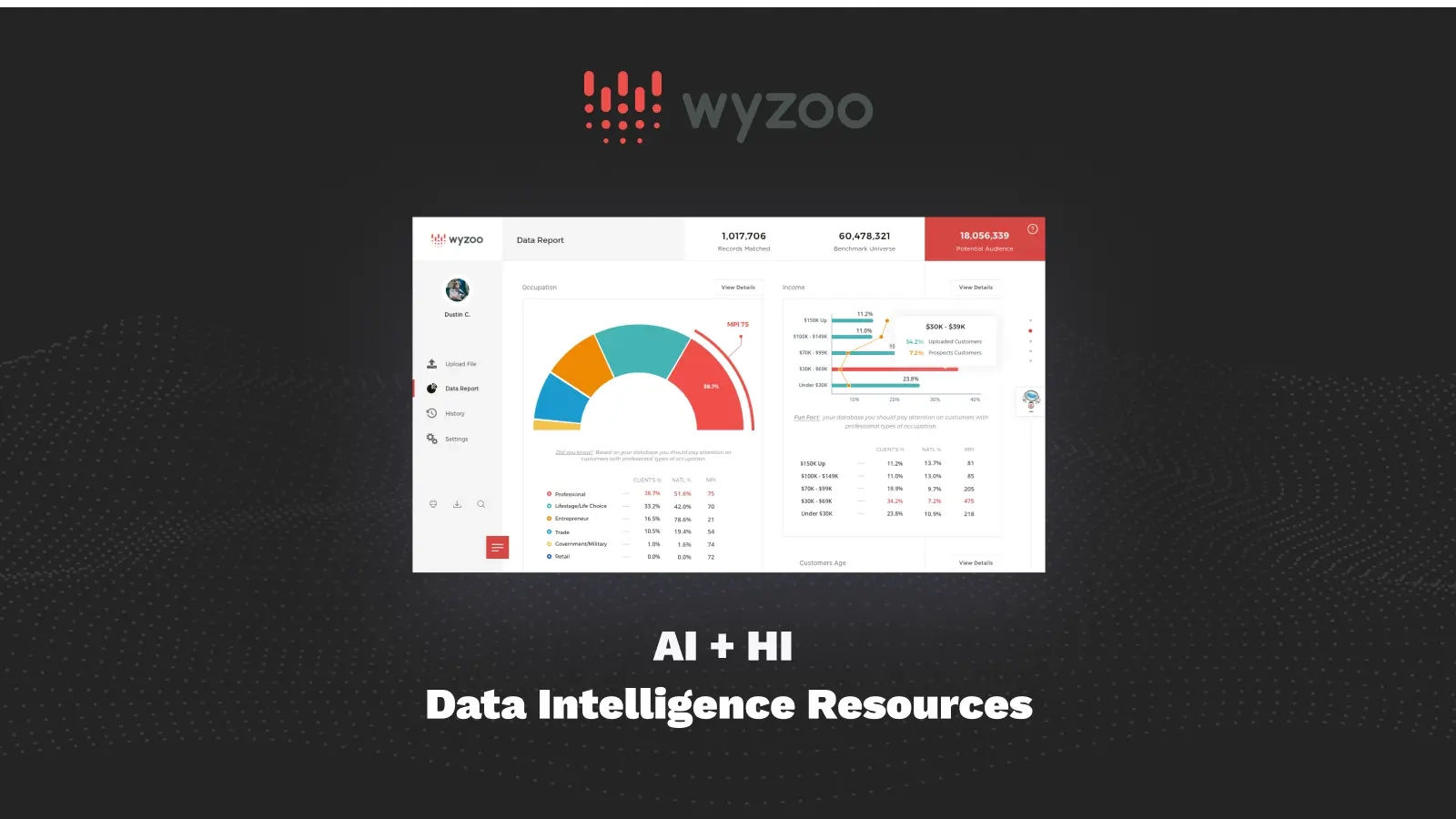

Reducing informational noise

AI-driven systems process large volumes of data instantly, isolating critical insights and filtering out unnecessary noise. This reduces the cognitive load on managers, enabling clearer decisions without distractions. For example, in our collaboration with Wyzoo, we developed a web platform integrating machine learning models to identify audience segments, optimize marketing decisions, and streamline data analysis.

Our success story:

Wyzoo – model prediction service

Wyzoo App is built on artificial intelligence and learning techniques to identify patterns in your customer data.

Enhanced fleet coordination

AI-powered dynamic route planning and load balancing synchronize fleets with precision, reducing idle time and improving fuel efficiency. These systems ensure timely deliveries even during peak demand or adverse weather conditions.

Inventory optimization

AI continuously monitors inventory across warehouses, ensuring optimal stock levels and preventing overstock or stockouts. Advanced algorithms analyze trends, seasonality, and current consumption rates to accurately predict future inventory needs. See how robotic solutions enhance warehousing in a real example — our data pipeline development services for robotics-enabled data streaming and process optimization.

AI-assisted risk mitigation

AI analyzes complex supply chain networks to identify risks like supplier issues or geopolitical challenges, enabling proactive measures that safeguard operations and prevent costly delays. Explore our case study on building technology company software, where we used Google Cloud Platform to create secure, scalable solutions that integrate with diverse protocols and systems. The platform analyzes GSM data, ensuring compliance and delivering actionable insights through interactive dashboards.

Genuisee’s expertise in AI development and integration

At Genuisee, we bring deep expertise in AI solution development, enabling businesses to overcome operational challenges and optimize logistics and transportation processes. Our tailored AI solutions address complex issues, streamline workflows, and drive measurable improvements in efficiency, accuracy, and cost savings.

Nimble AI

Genuisee collaborated with Nimble AI to develop a versatile, intelligent warehouse robot capable of performing core fulfillment functions. The project involved creating a robust data pipeline to ensure seamless aggregation of delivery information across multiple services. By integrating AI-driven metrics, we enabled the system to:

Detect anomalies and prevent data loss

Reduce latency in data processing to under 30 seconds

Accelerate issue identification and resolution to just 30 minutes

These advancements allowed the client to centralize their data management processes, improve warehouse efficiency, and cut operational costs threefold.

AI-driven manufacturing system

In this project, Genuisee developed predictive analytics models to optimize demand forecasting. Using historical sales data and seasonality patterns, we designed AI systems that ensured accurate inventory management while reducing overstock and storage expenses. Key achievements included:

Improved demand prediction accuracy by 8%, ensuring timely deliveries

Reduced excess inventory levels by 10%, freeing up valuable warehouse space

Enhanced supply chain responsiveness by optimizing delivery schedules

These outcomes empowered the client to meet customer demands while minimizing costs and maintaining operational balance.

Thank you for Subscription!

The final word

You’ve seen how AI in logistics and transportation brings transformative advancements such as autonomous vehicles, predictive maintenance, and dynamic fleet coordination. These innovations go beyond solving inefficiencies — they enable your team to focus on meaningful, strategic work while fostering smarter workflows and more adaptive, precise operations across your supply chain.

At Genuisee, we work alongside you to create bespoke AI systems tailored to your goals. From real-time data insights to intelligent automation, our solutions integrate seamlessly into your operations to deliver measurable impact. Reach out today and discover how we can elevate your logistics and transportation business with AI.