Robotic Process Automation (RPA) is a must-have to grow your business in the manufacturing industry. We’re not exaggerating!

RPA in the manufacturing can do repetitive and boring tasks more efficiently than a human. In the manufacturing industry, it’s a game-changing technology.

A Deloitte study shows that over 53% of businesses have started using RPA in their workforce, and about 78% plan to re-invest in the tech within the next three years.

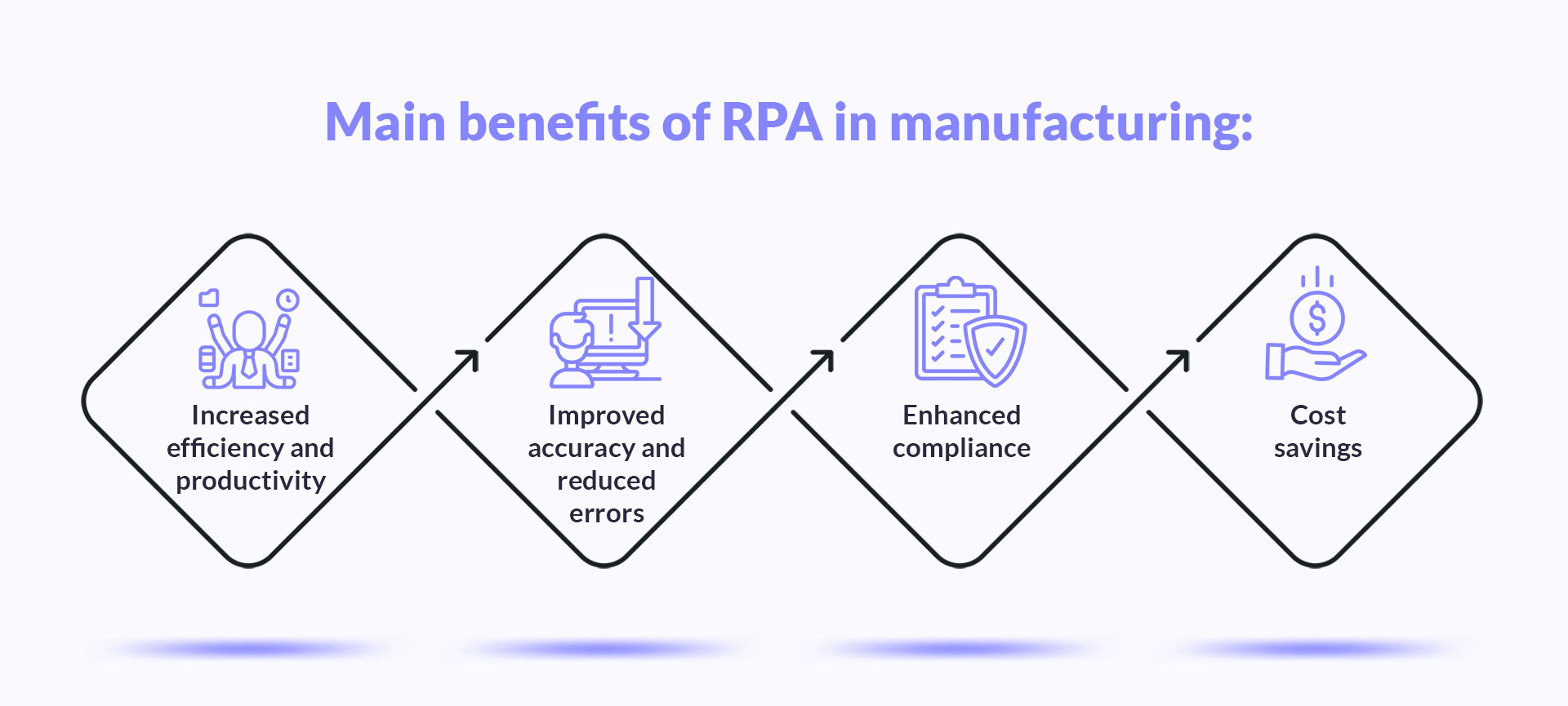

The benefits of RPA in manufacturing and modern business processes are clear: increased productivity, cost reduction, stringent quality control, better compliances, and faster time-to-market of your product. For instance, RPA enables human workers to focus on core business activities in the manufacturing industry. It automates repetitive tasks like sending reports.

In this article, you’ll learn about RPA in manufacturing and how it can benefit your business in the future, setting you up for success and bringing digital transformation.

After reading this, you can make an informed decision and know the benefits of RPA in the manufacturing industry.

What is RPA?

Would you perform repetitive tasks daily that can easily be automated? You wouldn’t, right? So, why would you let your employees do it and decrease your organizational productivity?

Robotic Process Automation (RPA) is computer-coded software (not physical robots) that replaces humans for rule-based and repetitive tasks. Your business can also integrate it with technologies like computer vision to enhance its capabilities.

It works as humans do and handles multiple tasks simultaneously. One of the benefits of RPA in manufacturing is performing data analytics, report generation, payroll and invoicing, customer support, and moving files and folders.

RPA automates routine tasks and reduces human errors. It is one of the fastest-rising technologies in multiple industries. Over 80% of finance industry leaders have adopted it.

RPA for manufacturing works in simple ways. It uses software robots to mimic and follow humans. It completes tasks and easily predicts rule-based processes. RPA solutions automate the mundane tasks that take up much time in manufacturing operations.

In the manufacturing industry, RPA can automate back-office processes. While the manufacturer has multiple responsibilities, RPA easily automates by integrating it with artificial intelligence and machine learning automation, a smart and rising innovation by 2025.

RPA solutions are also efficient. The proof? According to Gartner, almost 85% of large corporations integrated RPA in 2022, and by 2025, it will grow to approximately $22 billion. RPA use cases in a manufacturing company bring digital transformation to the business.

More from our blog:

NLP vs LLMs vs deep learning models

Thinking about using AI like ChatGPT or Midjourney in your business? Discover the key differences between NLP, LLM, and DLM.

Read nowBenefits of RPA in manufacturing

Let's examine how RPA in manufacturing can transform your business. Here are some key advantages:

1. Increased efficiency and productivity

RPA does the monotonous repetitive processes in business, ensuring humans do the core business activities. In the manufacturing industry, RPA can handle time-consuming tasks such as:

Inventory levels and supply chain management: It helps optimize inventory collection and supply chain management operations, including accepting orders, delivering and managing inventory, and the supply chain process. Essentially, inventory management becomes more efficient in your business.

Order process: Order processing is faster and error-free for customer transactions.

Lining up the order processing: Order prioritizing is important and done automatically with the RPA automation process.

Payroll management: Payments are processed automatically, on time, and error-free.

Accelerating the manufacturing process: Accelerating manufacturing generates more revenue and productivity, ultimately raising supply chains.

For example, Eastman Chemical, a chemical manufacturing company, has saved hours of manual work and resources. RPA brought them efficiency by speeding up the process, maintaining production schedules, and automatically processing purchase orders.

2. Improved accuracy and reduced errors

Your company can’t afford errors because they create huge losses. Achieving perfection is an exaggeration, but with robotic process automation in manufacturing, you get accurate results without errors. It handles:

Accurate data migration and entry management: It ensures precise data migration and management.

Consistent and error-free data analytics: Accurate data and analytics are important for all business types.

Bring accurate leads for informed decision-making: Accurate data is used to develop business strategies and make informed decisions.

For example, Hovis, a food manufacturer, automated its finances and human resources with RPA. In companies where data is the primary working process, it is expected to be error-free, and that’s where RPA comes into action by automating the data updates.

3. Enhanced compliance

RPA solutions simplify work by automating it. It easily maintains error-free records and helps manage the data regularly and on point.

Tasks that RPA bots can handle include:

Automated audits: Robotic process automation in manufacturing helps regularly perform predictive maintenance audits and manual process interventions. Business process automation seamlessly optimizes the overall workflow, reducing human errors. Almost 50% of companies spend more than $25 for manual invoice processing, but RPA helps cut costs.

Accurate documentation: Manufacturing companies need accurate documents during regulatory compliance audits or inspections. Document processing is crucial and becomes easier with RPA.

Enhanced reporting: RPA helps accurately report precise data to strategize the business process and have a comprehensive overall view.

Risk-free mitigation: RPA ensures accurate and timely maintenance of the legalization process, which prevents unnecessary fines or legal issues. Deploying RPA offers peace of mind.

Boosted manufacturing capabilities: With RPA bots, you easily complete complex manufacturing process tasks, and it helps manage your ERP system automatically.

4. Cost savings

RPA implementation reduces labor costs in the business process and manufacturing industry. Your business has streamlined processes, accurate demand forecasting, and increased production, which saves costs—all thanks to the RPA used in manufacturing.

The technology lowers labor costs, helping your production planning. For instance, it can perform price forecasting, which impacts production and helps the manufacturing process.

For example, AGCO, an agricultural machinery manufacturer, reduced overtime costs by automating them with RPA bots, ultimately earning more benefits in the business.

Implementation considerations for manufacturing

We know that RPA reduces manual processes and tasks by almost 67%. However, implementing RPA in the manufacturing sector is more than that. Every industry has different RPA use cases, and nearly every industry can integrate them.

The manufacturing industry (35%) is at the top for implementing RPA. Here are stats for other industries (source of the stats):

Technology sector (30%)

Healthcare industry (10%)

CPG industry (8%)

Finance sector (8%)

Education sector (3%)

You know the usage of RPA in the manufacturing industry, but other sectors are gradually adopting RPA for their operations.

The process and goal of RPA are simple. It manages repetitive tasks considering the monetary compilation and consistently manages the production range.

Large companies have large volumes of processes and data to manage, making RPA technology easier to handle. For RPA implementation, here are some tasks your business can efficiently manage after integrating RPA:

Purchase orders creation

Supply chain optimization

Vendor communication

Invoice processing and billing

Reporting and administrative tasks

24/7 customer support

Product and logistic data

Inventory management

Thank you for Subscription!

Every organization’s needs are different. Your company may not need the automation processes that another company demands. For instance, a tech company might need RPA for website scraping, while a manufacturing company would need it for reporting purposes.

In conclusion, you must consult and research to determine which processes your business needs to automate with RPA.

You know the key benefits, but there are challenges with RPA implementation, including employee training, significant investment costs, and management changes.

Team members and employees should be trained on RPA bots to use the intelligent automation process efficiently. Here are some benefits to consider:

Improved health security for manufacturing industry employees.

Risk management process can be taken over by robots and automated in the production line and manufacturing process.

Human risk is decreased, which leads to a safer place for employees.

RPA automation does not eliminate jobs but has been upgraded with digital transformation to improve job quality control.

Employees can change from repeated and monotonous tasks to better roles.

Skills can be better utilized, and employees’ personal growth is considered while learning RPA solution processes in the company.

Additionally, integrating RPA intelligent automation is not free, and setup requires a significant investment.

The manufacturing sector must undergo operational and cultural changes for RPA deployment, so it is important to ensure a smooth process. However, for quality control, it is a highly secure process.

Implementing RPA may feel overwhelming, but Geniusee’s services can help you navigate the complexities of your manufacturing business.

Conclusion

Now you know how RPA (Robotic Process Automation) can be a game-changer for a manufacturing company. It can automate monetary compliance and bill of materials (BOM), order fulfillment and shipping processes, inventory management, invoice processing, and inventory reporting, and it can easily integrate with ERP systems.

The RPA market is expected to rise by 2025 and bring significant changes to manufacturing companies. Installing RPA is more than modernization in manufacturing organizations.

Advance and see the progress in manufacturing businesses. RPA frees you from manual processes and efforts. It helps you make informed decisions, which reduces human errors and generates more revenue for the business.